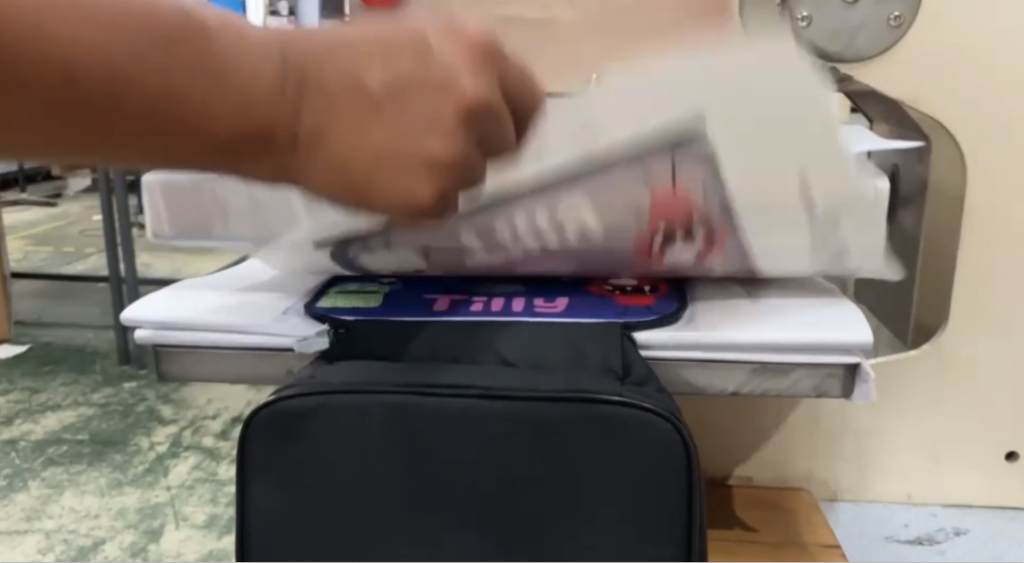

Each custom Bega lunch bag was made to order, eliminating excess stock, reducing waste, and ensuring every piece felt genuinely personal. Our streamlined workflow delivered faster turnaround times and consistent brand quality, from screen to doorstep.

Every step was handled in-house through TPF’s integrated fulfilment network. Once a user finalised their design, the order data flowed directly into our production system, triggering automated printing, quality assurance checks, and packaging before dispatch.

Our real-time tracking and reporting systems provided complete visibility for both the client and internal teams. Automated notifications, order status updates, and performance dashboards kept every element running smoothly and transparently.